The increasing popularity of Just-In-Time (JIT) methods and high-quality information flow has applied increased pressure on supply chain management performance. Better throughput, more product lines and value-added services are now expected to alleviate the uncertainty in demand. Subsequently, the objective is to synchronise the manufacturer and the customer for a flow-through operation that minimises the costs and risks of warehousing.

WayCool, India’s largest agri-commerce company, is transforming the country’s food economy through this very same supply chain proposition. We identified and implemented Cross Docking automation to eliminate storage and corresponding handling costs in less-than-truckload and full truckload shipments.

This has helped us significantly reduce the dispatch time while accentuating the transfer efficiency between the terminals.

Our Chromepet Distribution Centre (DC) required manual unloading and customer or dispatch-wise segregation of all materials on the dock. A stringent manual inspection followed this, adding to the operation time and sub-optimal inbound and outbound documentation assignment. With an expansive range of crates, bags, and carton boxes, load consolidation was getting increasingly cumbersome considering the rising number of daily shipments. The excessive need for manual inspection at every touchpoint meant a long supply chain for us, thus calling for the need to find alternative methodologies.

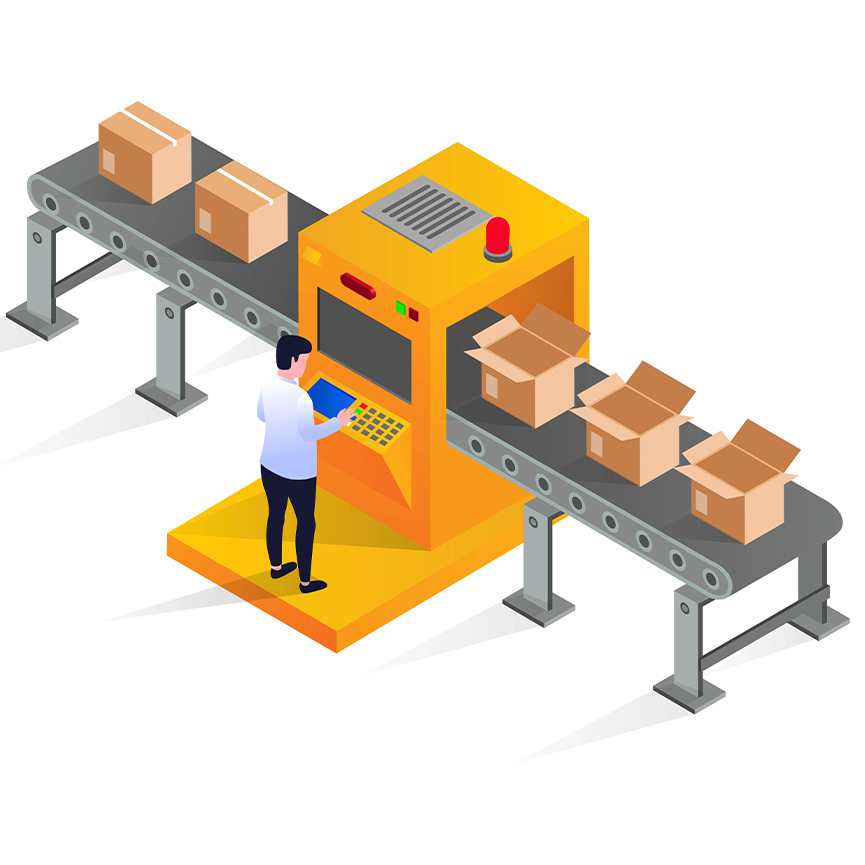

In line with the Cross Docking automation objectives, we applied a standard distribution practice via conveyor belts that segregate the crates zone-wise within the route itself. The crates are then automatically placed in the outbound delivery vehicles by customer-wise dispatch sorting.